Nails for framing are available in various surface finishes, each offering unique properties and benefits.

Some common types of surface finishes for framing nails include:

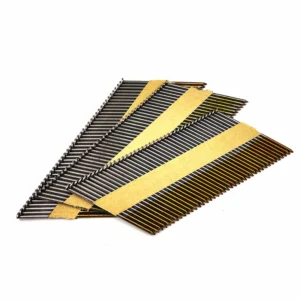

- Bright Finish: Bright finish nails are uncoated and have a natural metallic appearance. They are economical and widely used for general framing applications. However, they are more prone to corrosion and may leave visible marks on the wood surface over time.

- Hot-Dip Galvanized: Hot-dip galvanized nails are coated with a layer of zinc by dipping them into molten zinc. This coating provides excellent corrosion resistance, making them suitable for outdoor and high-moisture environments. Hot-dip galvanized nails have a dull gray appearance due to the zinc coating.

- Electro-Galvanized: Electro-galvanized nails are coated with a thinner layer of zinc using an electroplating process. While not as durable as hot-dip galvanized nails, electro-galvanized nails still offer good corrosion resistance and are suitable for many framing applications. They have a shinier appearance compared to hot-dip galvanized nails.

- Mechanical Galvanized: Mechanical galvanized nails undergo a process where zinc particles are bonded to the nail surface through mechanical means, such as tumbling or spraying. This coating provides corrosion resistance similar to hot-dip galvanizing but with a smoother finish.

- Stainless Steel: Stainless steel nails are made from corrosion-resistant steel alloys, such as 304 or 316 stainless steel. They offer superior resistance to rust and corrosion, making them ideal for outdoor and marine applications. Stainless steel nails have a shiny silver appearance.

- Vinyl-Coated: Vinyl-coated nails have a layer of vinyl or plastic coating applied to the surface, providing additional corrosion resistance and reducing the risk of surface damage to the wood. They are available in various colors to match different wood finishes and are often used for trim and finish work.

- Blued: Blued nails are treated with heat to create a thin oxide layer on the surface, giving them a blue-black appearance. This finish provides some corrosion resistance and helps reduce friction during driving, making them easier to install.

The choice of surface finish for framing nails depends on factors such as the application, environmental conditions, and aesthetic preferences. It’s essential to select the appropriate finish to ensure long-term durability and performance in framing construction.