How Filter Plates and Cloths Contribute to Primary Wastewater Treatment?

Filter plates and cloths are essential components in primary wastewater treatment using a filter press. The primary function of the filter plates and cloths is to separate the solid and liquid components of the wastewater, which is achieved through a filtration process.

Here’s how filter plates and cloths contribute to primary wastewater treatment:

Filtration: The filter plates and cloths are arranged in a stack in the filter press, with each plate separated by a filter cloth. The wastewater is pumped into the filter press and distributed evenly over the filter cloths. As the wastewater passes through the filter cloths, the solid components are trapped on the surface, forming a filter cake. The remaining liquid, or filtrate, passes through the filter cloth and is collected in a container.

Separation: The filter plates and cloths facilitate the separation of the solid and liquid components of the wastewater. The filter cake that forms on the surface of the filter cloth is removed from the filter press and disposed of, while the filtrate is further treated in secondary wastewater treatment processes.

Efficiency: The filter plates and cloths are designed to maximize filtration efficiency by providing a large surface area for the wastewater to pass through. This ensures that the maximum amount of solid material is removed from the wastewater, improving the overall efficiency of the treatment process.

Customization: The filter plates and cloths can be customized to meet specific wastewater treatment requirements. This includes the choice of filter cloth material, which can vary depending on the type of wastewater being treated, and the design of the filter plates, which can be optimized for specific filtration requirements.

In summary, filter plates and cloths play a critical role in primary wastewater treatment by facilitating the filtration and separation of solid and liquid components. filter press machine They contribute to the efficiency of the treatment process and can be customized to meet specific wastewater treatment requirements.

7 Tips For Better filter press machine

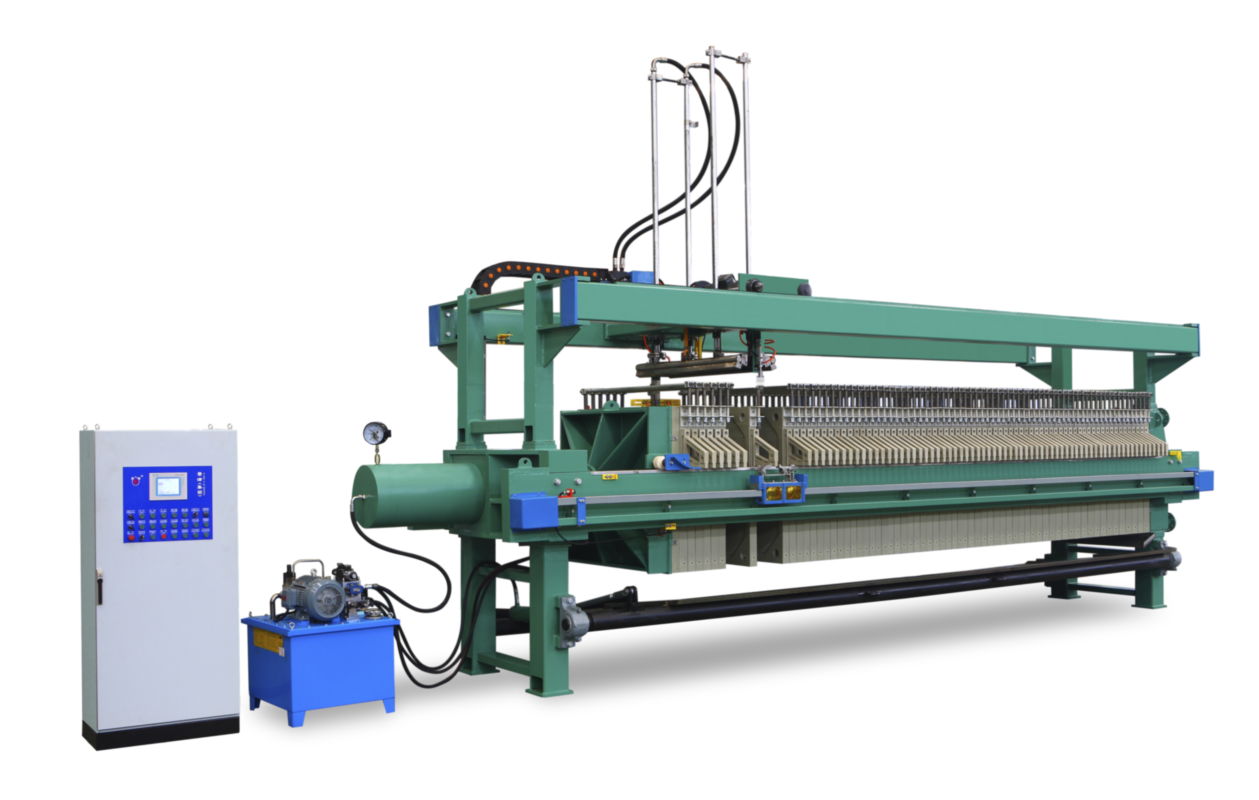

Filter press machines are essential equipment in a variety of industries, including chemical, mining, and wastewater treatment.

Here are seven tips to help you improve the performance and efficiency of your filter press machine:

- Regular maintenance: Regular maintenance of the filter press machine is essential to ensure that it operates at optimal efficiency. This includes cleaning and inspecting the machine, replacing any worn or damaged parts, and ensuring that the hydraulic system is functioning correctly.

- Monitor operating parameters: Monitoring the operating parameters of the filter press machine, such as pressure, flow rate, and cycle time, can help identify any issues early on and optimize the performance of the machine.

- Use the correct filter media: Using the correct filter media for the specific application is crucial to achieving optimal filtration performance. Selecting the appropriate filter media can improve the efficiency of the filtration process and reduce operating costs.

- Properly align filter plates: Properly aligning the filter plates is essential to ensure that the filter media is evenly distributed and that the machine operates efficiently. Misaligned filter plates can cause leaks and reduce filtration efficiency.

- Use the correct amount of filter aid: Using the correct amount of filter aid, such as diatomaceous earth or perlite, can improve the efficiency of the filtration process and reduce operating costs. Too little filter aid can result in poor filtration, while too much can cause clogging and reduce flow rates.

- Optimize cycle times: Optimizing the cycle times of the filter press machine can improve the efficiency of the filtration process and reduce operating costs. Longer cycle times can result in higher filtration efficiency but also increase operating costs.

- Properly dispose of filter cake: Properly disposing of the filter cake, the solid material left over after filtration, is essential to ensure compliance with environmental regulations. The filter cake can be hazardous and must be disposed of properly to avoid contamination.

By following these tips, you can improve the performance and efficiency of your filter press machine, reduce operating costs, and ensure compliance with environmental regulations.